Research on new

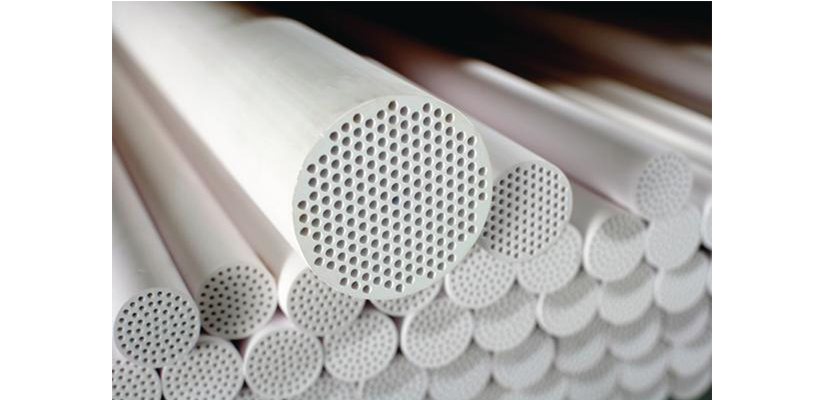

ceramic membrane materials is currently focused on two aspects. Synthetic ceramic membrane materials: mainly silicon carbide, mullite, cordierite, graphene and ceramic fibers. Natural ceramic membrane materials: mainly natural zeolite, fly ash, kaolin and attapulgite.

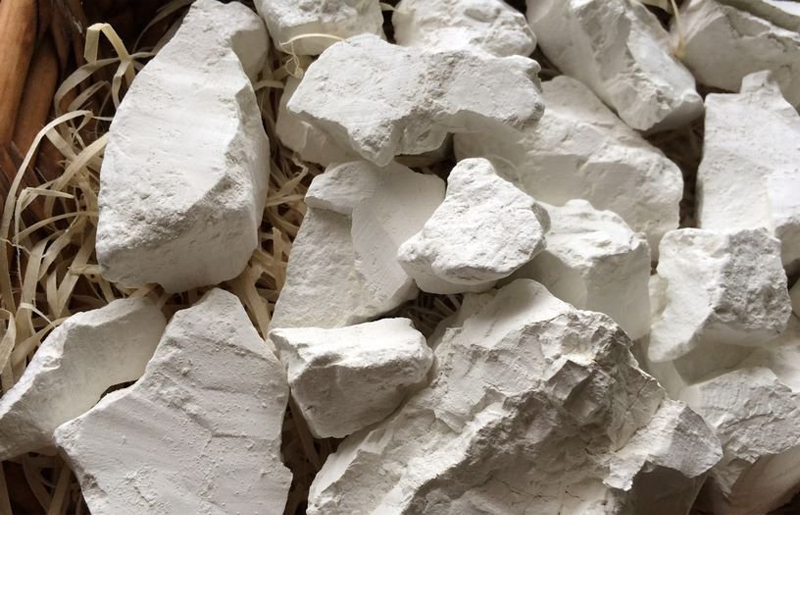

1. Natural zeolite

Natural zeolite has a special porous structure, a developed specific surface, and a rich surface hydroxyl group. Moreover, China's natural zeolite is rich in reserves and low in price. Therefore, processing natural zeolite into ceramic separation membrane can not only reduce the production cost of separation membrane, but also provide a new choice for the preparation of ceramic membrane.

For example, a natural zeolite ceramic membrane support is prepared by extrusion molding using natural zeolite as a main material. The average pore diameter was 6.6 μm and the porosity was 46%. Then, a natural zeolite suspension having a particle diameter of 2.1 μm and 0.5 μm was separately coated on the surface of the support by a dipping method to obtain a transition layer and a top film having an average pore diameter of 0.6 μm and 0.1 μm, respectively. The pure water flux of the entire asymmetric ceramic membrane reached 187 L/m2.h.bar.

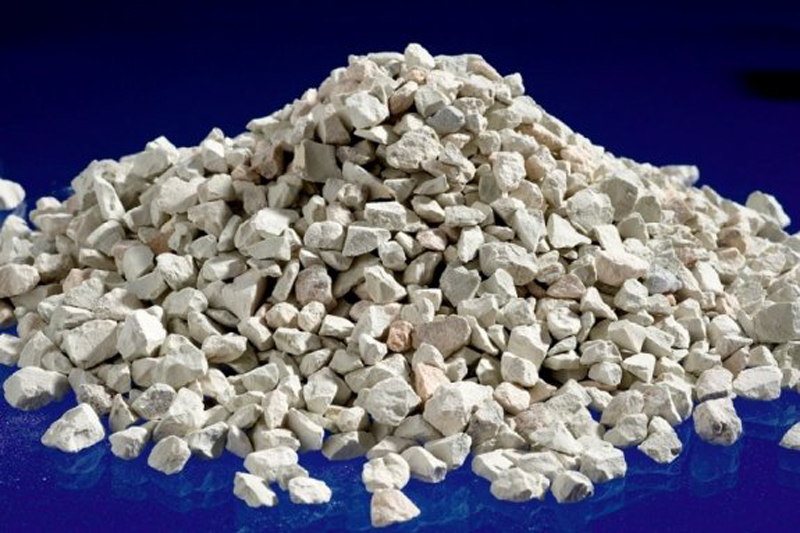

2. Fly ash

Fly ash is a waste and by-product of thermal power plants, and the pollution caused by the environment is very serious. Since the content of Al2O3 and SiO2 in fly ash reaches 8.65%, mullite with high refractoriness, low thermal expansion coefficient, chemical stability and thermal stability can be formed after high temperature sintering, so fly ash can prepare

ceramic membrane with excellent performance to turn waste into treasure.

A porous mullite

ceramic membrane support was prepared by in situ sintering at 1300 ° C using low-cost solid waste fly ash and raw bauxite as raw materials. Its open porosity is as high as 50%. The mullite phase content is as high as 86.75%. The mechanical strength of the support is as high as 69.87 MPa. A ceramic microfiltration membrane was prepared on the cordierite tubular support by using fly ash as raw material, sintered at 1150 ° C, with an average pore diameter of 5 μm and a porosity of 54%.

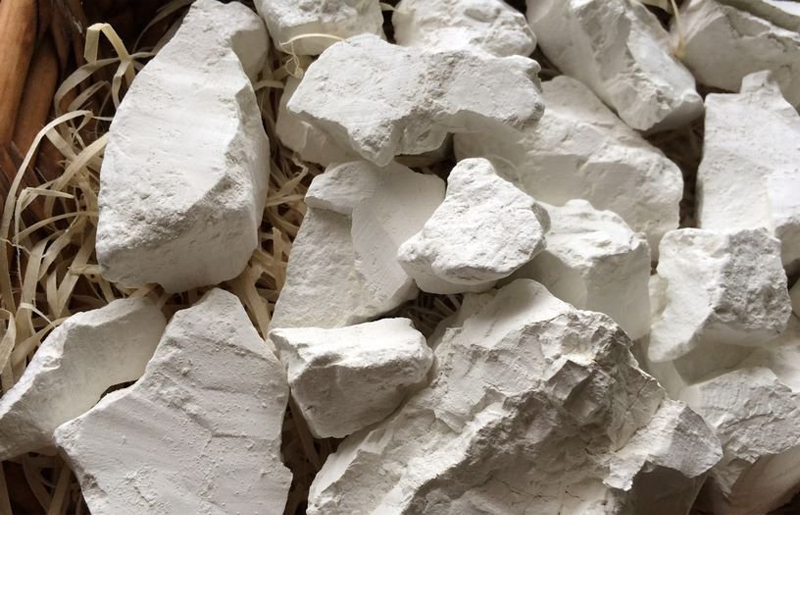

3. Kaolin

Kaolin (Al2O3-2SiO2-2H2O), also known as hydrated aluminum silicate china, is an important non-metallic mineral resource. It is widely distributed in China. Due to its low price and superior performance, it has attracted more and more attention in the field of ceramics.

For example, a ceramic microfiltration membrane having an average pore diameter of 1.3 μm, a mechanical strength of 34 MPa, and a porosity of 30% is produced by extrusion molding at 900 ° C using kaolin as a raw material.

Application Of Ceramic Membranes In Wine Industry And Its Application Prospects

01 Feb 2019

Application Of Ceramic Membranes In Wine Industry And Its Application Prospects

01 Feb 2019

Ceramic Membrane For Traditional Chinese Medicine Production And Plant Extraction

05 Feb 2019

Ceramic Membrane For Traditional Chinese Medicine Production And Plant Extraction

05 Feb 2019

Application Of Ceramic Membrane Equipment In Transformer Oil And Gas Separation

12 Feb 2019

Application Of Ceramic Membrane Equipment In Transformer Oil And Gas Separation

12 Feb 2019

Ceramic Membranes Are Used In The Automotive Field Due To Their Good Performance

27 Jan 2019

Ceramic Membranes Are Used In The Automotive Field Due To Their Good Performance

27 Jan 2019

+86-25-58849045

+86-25-58849045

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808