Transformer oil dissolved gas analysis is an important means of health monitoring of large oil-filled power equipment. By quantitatively analyzing the characteristic fault gas in the transformer insulating oil, the operating state of the transformer can be grasped in time, and then necessary maintenance can be performed. In view of the fact that there is currently no way to directly detect the gas dissolved in the oil, it is a key link to realize real-time online monitoring of the transformer by efficiently separating the fault gas dissolved in the transformer oil.

The early application of oil and gas separation methods mainly includes doppler degassing and partial degassing. They can basically achieve complete degassing, but require the piston to be vacuum processed, which is cumbersome to operate and is not suitable for online monitoring. In recent years, the research has been widely studied on polymer membrane dissolution-infiltration oil and gas separation methods, which are simple in structure and stable in performance. At present, most of the polymer membranes used are polytetrafluoroethylene propylene membrane (FEP), polytetrafluoroethylene capillary membrane (GPIOO), hollow fiber composite membrane, and microporous PTFE membrane. However, these organic polymer membranes also have a problem of low gas permeability and long on-line monitoring response time. The oil and gas balance time is often as long as ten or even several days, which does not meet the requirements of online monitoring.

Compared with organic polymer membranes,

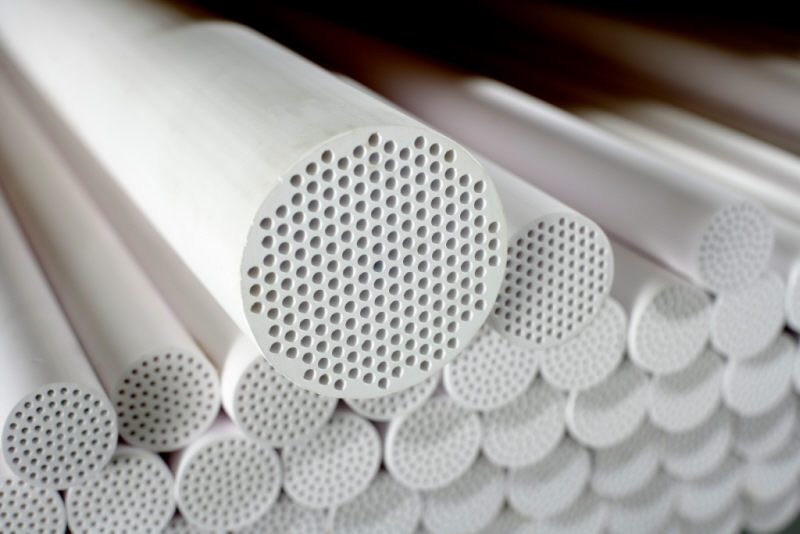

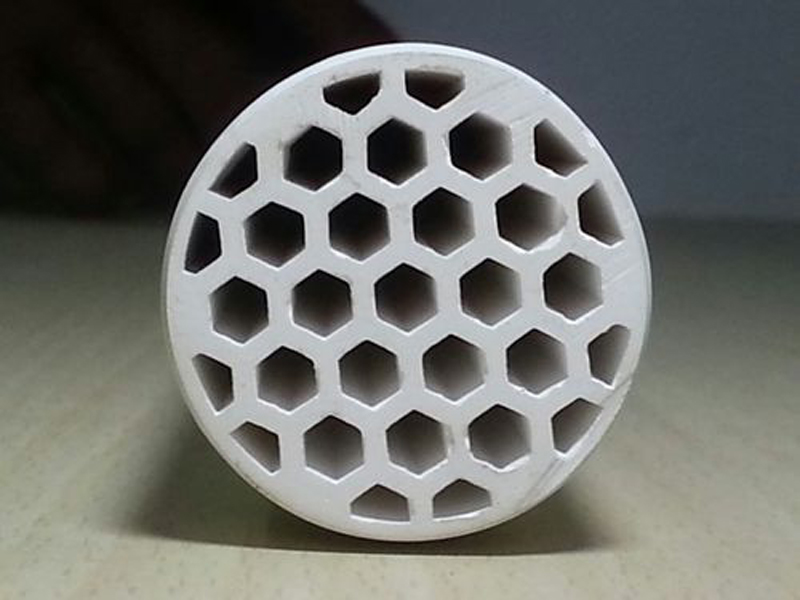

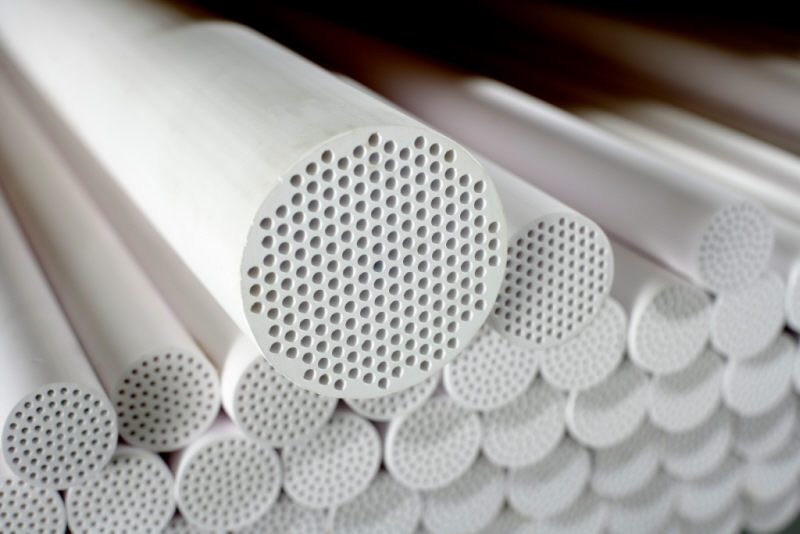

inorganic membranes have the advantages of high temperature resistance, microbial resistance, good chemical stability, high mechanical strength, easy cleaning and regeneration, and concentrated pore size distribution. Inorganic membranes have been used in the field of liquid separation such as foods and pharmaceuticals, and

ceramic membranes are more representative. Moreover, with the improvement of the preparation process of the ceramic membrane, the filtration pore size can reach below 3 Onm, which becomes a strong competitor of the organic polymer membrane. At home and abroad, there have been related researches on the application of organic polymer membranes in the field of transformer oil and gas separation, but no research work on oil and gas separation using ceramic membranes has been found. The ceramic membrane can be used alone for oil and gas separation. The ceramic membrane-based oil and gas separation membrane module is designed to test the component for the typical fault gas CzH of the transformer. It can be compared to traditional organic membranes.

The traditional organic membrane oil and gas separation mechanism can be described by a dissolution diffusion model. One side of the membrane is in direct contact with the transformer oil and the other side is an isolated small chamber. The gas molecules on both sides gradually become balanced due to thermal motion. After the equilibrium, the volume fraction of the gas in the gas phase has a certain conversion relationship with the volume fraction of the dissolved gas in the oil. Therefore, the concentration of the dissolved gas in the oil can be calculated by measuring the volume fraction of the gas in the gas chamber. This structure is relatively simple, but the traditional organic membrane generally has a fatal flaw - the balance time is relatively long.

Different from the traditional organic membrane, the microporous ceramic membrane is a fluid separation process in the form of "cross-flow filtration". The transformer oil flows at high speed in the membrane tube. Outside the membrane tube is a small isolated air chamber. The cross section of the ceramic membrane is a multi-channel tubular structure, and the tube wall is densely covered with micropores.

The oil and gas separation process of the ceramic membrane mainly relies on the thermal motion of the gas molecules to gradually balance the gas concentration inside and outside the oil. The difference is that the transformer oil will generate internal pressure during the flow in the membrane tube, and it will penetrate vertically in the vertical direction under the pressure. The oil pressure gradually decreases during the infiltration process, resulting in a decrease in the solubility of the faulty gas dissolved therein, thereby making it easier for the gas molecules to escape and shortening the time required for the balance. In addition, this form of filtration greatly increases the area of filtration compared to the terminal filtration form of conventional organic membranes, making it easier to achieve shorter equilibration times. The end result is that the transformer oil containing the macromolecular component is trapped by the membrane separation layer, and the small molecule gas is separated through the wall of the ceramic membrane to achieve the purpose of oil and gas separation.

JIUWU HI-TECH has always been market-oriented and actively explores the application of membrane technology in different fields. JIUWU HI-TECH constantly understands customer needs and quickly meets the ever-changing customer needs through improvement and innovation to provide satisfactory services to customers.

Application Of Ceramic Membranes In Wine Industry And Its Application Prospects

01 Feb 2019

Application Of Ceramic Membranes In Wine Industry And Its Application Prospects

01 Feb 2019

Ceramic Membrane For Traditional Chinese Medicine Production And Plant Extraction

05 Feb 2019

Ceramic Membrane For Traditional Chinese Medicine Production And Plant Extraction

05 Feb 2019

Application Of Ceramic Membrane Equipment In Transformer Oil And Gas Separation

12 Feb 2019

Application Of Ceramic Membrane Equipment In Transformer Oil And Gas Separation

12 Feb 2019

Ceramic Membranes Are Used In The Automotive Field Due To Their Good Performance

27 Jan 2019

Ceramic Membranes Are Used In The Automotive Field Due To Their Good Performance

27 Jan 2019

+86-25-58849045

+86-25-58849045

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808