The international

membrane technology industry has begun to take shape. In 1998, there were 452 membrane and membrane equipment manufacturers and operating companies announced on the Internet abroad, including 50 metal membrane factories and 94 ceramic membrane production plants.

JIUWU HI-TECH is China's largest producer of

ceramic membranes.

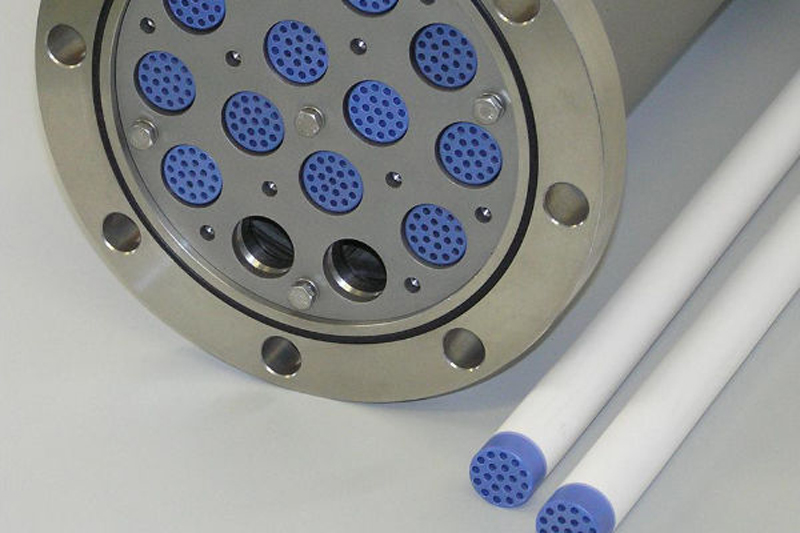

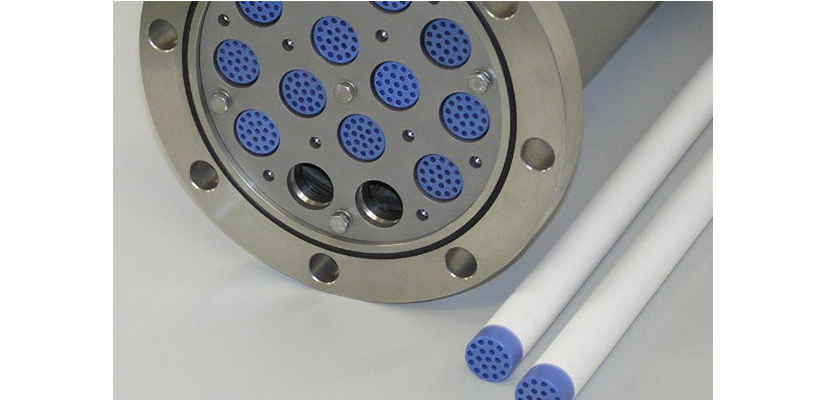

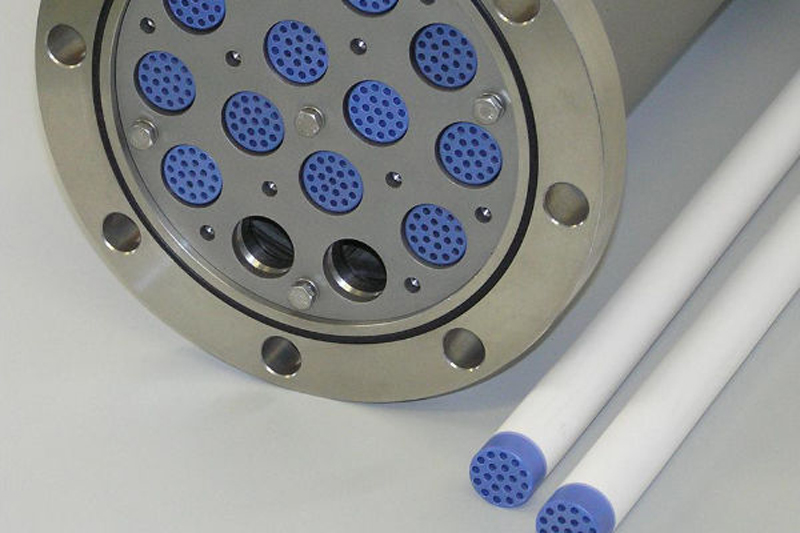

At present, the commercial porous ceramic membranes are mainly configured in three types: flat plate, tubular type and multi-channel. Flat membranes are mainly used for small-scale industrial production and laboratory research. The tubular membranes are combined to form a tube-like heat exchanger that increases the membrane loading area, but has gradually withdrawn from industrial applications due to its strength problems. Ceramic membranes for scale applications typically employ a multi-channel configuration in which a plurality of channels is distributed over a circular cross section, typically having a number of channels of 7, 19 and 37.

The main preparation techniques of the inorganic ceramic membrane include: The carrier and the microfiltration membrane are prepared by solid particle sintering. An ultrafiltration membrane was prepared by a sol-gel method. A glass film was prepared by a phase separation method. Microporous or dense films are prepared using specialized techniques such as chemical vapor deposition, electroless plating, and the like. The basic theory involves colloid and surface chemistry, material chemistry, solid state ionics, and material processing in materials science.

From the development trend, the development of membrane preparation technology is mainly in the following two aspects: First, in the research of porous membrane, further improve the commercial inorganic ultrafiltration and microfiltration membrane, and develop nanofiltration membrane, gas separation membrane and the pervaporation membrane with molecular sieve function. Second, in the study of dense membranes, ultra-thin metals and their alloy membranes and solid electrolyte membranes with ion-electron mixed conductivity are the research hotspots. The porous membranes which have been commercialized are mainly ultrafiltration and microfiltration membranes, and the preparation methods thereof are mainly particle sintering method and sol-gel method. The former is mainly used for the preparation of microporous membranes, and the widely used commercial al2o3 membrane is prepared by particle sintering. Commercially available ultrafiltration membranes such as γ-al2o3, tio2, sio2, and zro2 membranes are prepared by a sol-gel method.

The development of membrane technology is becoming more and more mature. JIUWU HI-TECH is the largest membrane technology company in China and is committed to becoming a leader in the global membrane separation industry.

Application Of Ceramic Membranes In Wine Industry And Its Application Prospects

01 Feb 2019

Application Of Ceramic Membranes In Wine Industry And Its Application Prospects

01 Feb 2019

Ceramic Membrane For Traditional Chinese Medicine Production And Plant Extraction

05 Feb 2019

Ceramic Membrane For Traditional Chinese Medicine Production And Plant Extraction

05 Feb 2019

Application Of Ceramic Membrane Equipment In Transformer Oil And Gas Separation

12 Feb 2019

Application Of Ceramic Membrane Equipment In Transformer Oil And Gas Separation

12 Feb 2019

Ceramic Membranes Are Used In The Automotive Field Due To Their Good Performance

27 Jan 2019

Ceramic Membranes Are Used In The Automotive Field Due To Their Good Performance

27 Jan 2019

+86-25-58849045

+86-25-58849045

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808