Under the pressure of “the most stringent environmental protection policy in history”, silicon carbide

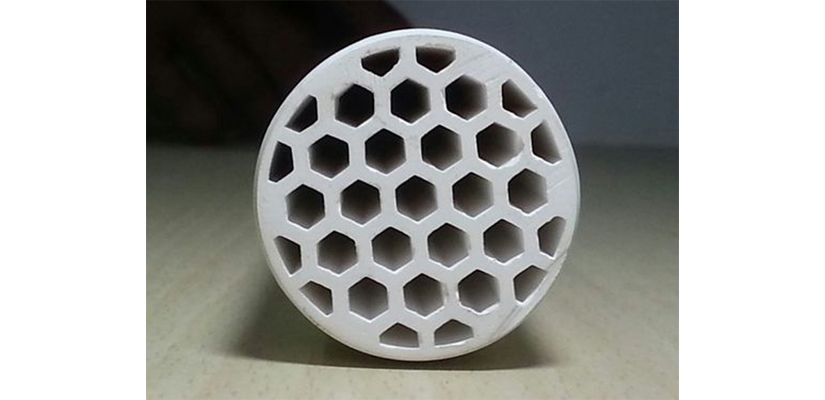

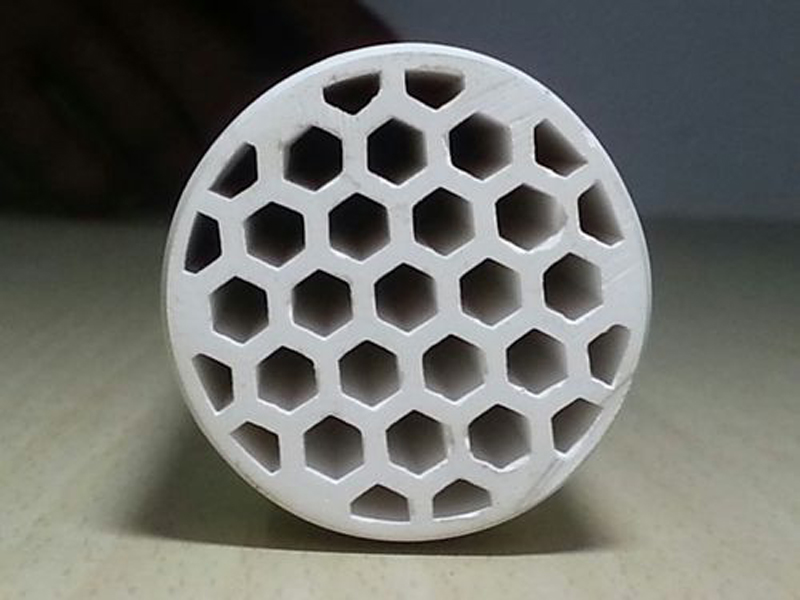

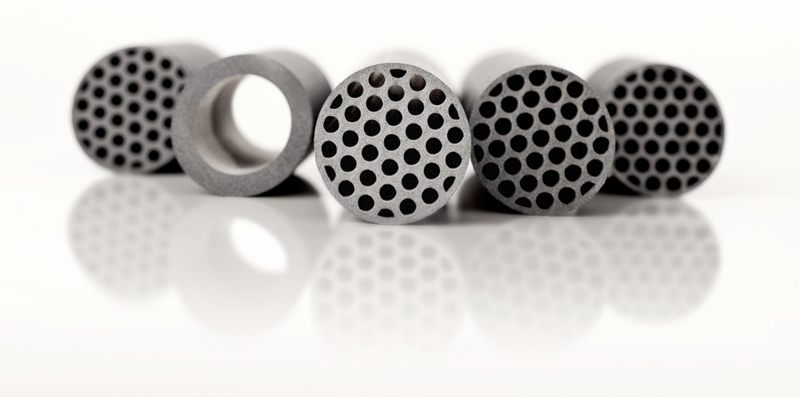

ceramic membranes have become a hot topic. In the field of wastewater and waste gas treatment, silicon carbide ceramic membranes can be used. This is because the pore size of silicon carbide ceramic membranes currently available in the market can reach 40 nanometers. The molecular diameters of water, nitrogen and oxygen are basically around 0.3 nm, so the silicon carbide ceramic membrane can easily pass water or gas, and is filtered out for impurities, even viruses, bacteria, etc. (Note: bacteria diameter is generally 1 μm - 10 μm Viruses range from 20 nm to 450 nm. Therefore, bacteria are easier to remove).

The cold sterilization technology is adopted to filter the yeast and impurities in the rice wine by using the silicon carbide

ceramic membrane filter, which can solve the problem that the yellow wine continues to ferment and acidify with the increase of temperature. Practice has proved that the rice wine treated by the silicon carbide

ceramic membrane filtration equipment has been stored under natural conditions of direct sunlight for nearly 3 months, and there is no secondary fermentation and rancidity such as sedimentation, turbidity and swelling.

Through the silicon carbide ceramic filter membrane, the acetic acid bacteria in the brewing process are effectively removed, so that the wine is not made into vinegar. With the introduction of 20nm, 10nm, 1nm silicon carbide

ceramic membrane products, it is believed that the application space of silicon carbide ceramic film will be even larger. Bacteria and viruses can be completely removed by filtration.

Application Of Ceramic Membranes In Wine Industry And Its Application Prospects

01 Feb 2019

Application Of Ceramic Membranes In Wine Industry And Its Application Prospects

01 Feb 2019

Ceramic Membrane For Traditional Chinese Medicine Production And Plant Extraction

05 Feb 2019

Ceramic Membrane For Traditional Chinese Medicine Production And Plant Extraction

05 Feb 2019

Application Of Ceramic Membrane Equipment In Transformer Oil And Gas Separation

12 Feb 2019

Application Of Ceramic Membrane Equipment In Transformer Oil And Gas Separation

12 Feb 2019

Ceramic Membranes Are Used In The Automotive Field Due To Their Good Performance

27 Jan 2019

Ceramic Membranes Are Used In The Automotive Field Due To Their Good Performance

27 Jan 2019

+86-25-58849045

+86-25-58849045

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808