As we all know, the application of ceramic membrane is very extensive. Below, we will introduce you to the specific characteristics of ceramic membrane and the application of membrane separation technology in the lactic acid production industry.

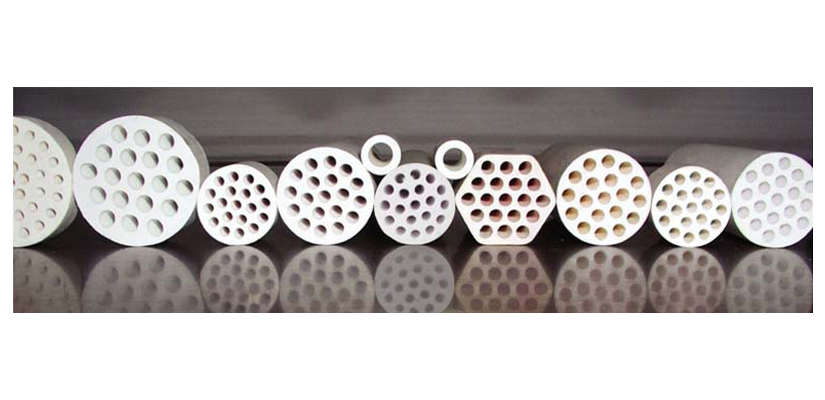

There are many characteristics of ceramic membranes:

1. Its raw material source is very wide, and the price is relatively affordable. It has its own advantages over ultrafiltration and reverse osmosis membranes.

2. It has high mechanical strength. If it is under a large pressure difference, it will not deform, especially for higher pressure recoil, which can be carried out stably. It is very resistant to high temperatures and is stable at temperatures below a thousand degrees.

3. It has good chemical properties, can be effective against microorganisms, has high endurance for corrosive gases, and it gives us good stability. It can be cleaned with strong acid.

At present, China's

lactic acid production industry is in a critical period of transition from quantity expansion to quality and efficiency. The key technologies of

lactic acid production processing focus on membrane separation technology, biotechnology (including genetic engineering, cell engineering, enzyme engineering, fermentation engineering and biochemical engineering), cold sterilization technology, detection technology, rheological analysis technology and freeze drying technology, cheese processing technology and whey comprehensive utilization technology, direct injection starter production technology.

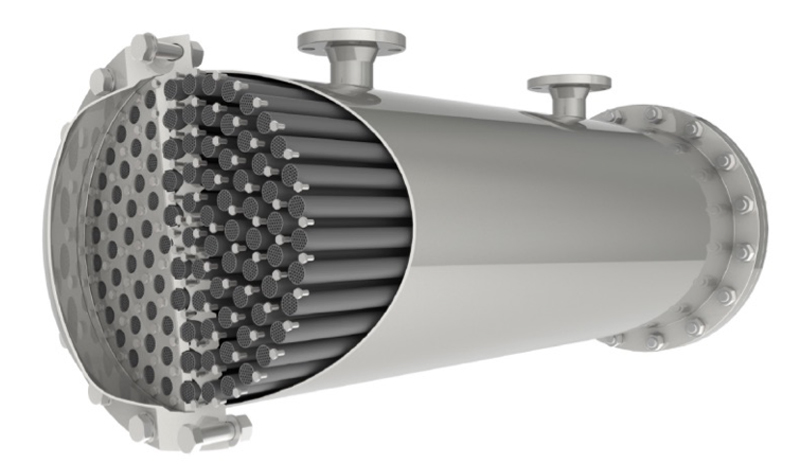

Lactic acid production processing equipment focuses on the development of large-scale milk powder production equipment for daily processing of raw milk over 500 tons, low-temperature spray drying equipment, cheese production equipment for daily processing of 100 tons of raw milk, membrane filtration equipment, economical multi-effect equipment, cream separation equipment, sterilization and aseptic filling equipment, whey processing equipment and milking equipment. It also develops methods and equipment for rapid detection of raw materials and finished products, on-line inspection of production processes and non-destructive testing.

Application Of Ceramic Membranes In Wine Industry And Its Application Prospects

01 Feb 2019

Application Of Ceramic Membranes In Wine Industry And Its Application Prospects

01 Feb 2019

Ceramic Membrane For Traditional Chinese Medicine Production And Plant Extraction

05 Feb 2019

Ceramic Membrane For Traditional Chinese Medicine Production And Plant Extraction

05 Feb 2019

Application Of Ceramic Membrane Equipment In Transformer Oil And Gas Separation

12 Feb 2019

Application Of Ceramic Membrane Equipment In Transformer Oil And Gas Separation

12 Feb 2019

Ceramic Membranes Are Used In The Automotive Field Due To Their Good Performance

27 Jan 2019

Ceramic Membranes Are Used In The Automotive Field Due To Their Good Performance

27 Jan 2019

+86-25-58849045

+86-25-58849045

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808