Enzyme membrane concentration process:

Fermentation liquid→ceramic membrane or tubular membrane→filtrate→ultrafiltration concentration→drying→solid product

Enzyme membrane separation and concentration technology:

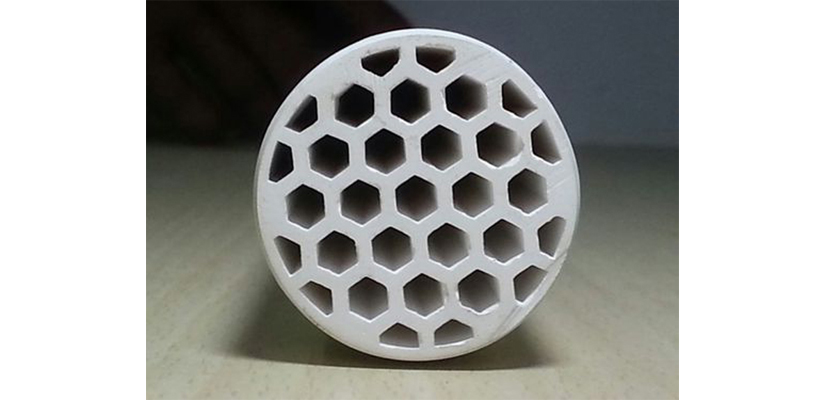

1. Enzyme preparation ceramic membrane microfiltration technology

The living cells are basically not inactivated, greatly improving the competitiveness of the products, and greatly improving the yield of the products, and ensuring the high profits of the enterprises to the greatest extent. At the same time, the membrane filtration of the ceramic membrane is not only the high retention of the living state of the living cells, but also the separation of the clear supernatant of the enzyme with high clarity, which reduces the production load of the downstream concentration process and protects the downstream membrane.

2. Enzyme preparation ultrafiltration concentration technology

In the ultrafiltration process, some pigments and heteroproteins and most inorganic salts are removed at the same time, which greatly improves the quality and stability of the product. At the same time, the ultrafiltration concentration is carried out at normal temperature, and the enzyme activity is not lost, and the yield is high. Furthermore, the membrane system is simple to operate, greatly reducing labor intensity and greatly reducing the concentration time. The ultrafiltration system has very little wastewater discharge, which reduces the environmental pressure to a certain extent.

Enzyme membrane concentration process advantages:

1. Membrane concentration is a purely physical process. It does not chemically react and does not introduce new impurities;

2. The membrane concentrating equipment system operates at low temperature. It has no phase change, qualitative change, does not destroy the active ingredients, and greatly reduces energy consumption; it is especially suitable for the concentration of materials with strong heat sensitivity;

3. The membrane concentration equipment has high filtration precision, can shorten the production cycle, improve the filtration efficiency, and can achieve a good clarification effect, and the process is stable and reliable;

4. While the membrane concentrates the biological fermentation liquid, a large amount of inorganic salts can be extracted and the product can be purified;

5. The cross-flow operation process of membrane concentration completely solves the problem of pollution blockage;

6. The membrane concentration equipment is highly automated, safe and reliable, and effectively reduces the labor intensity. The membrane separation process is carried out in a closed container, which can achieve clean production well.

Application Of Ceramic Membranes In Wine Industry And Its Application Prospects

01 Feb 2019

Application Of Ceramic Membranes In Wine Industry And Its Application Prospects

01 Feb 2019

Ceramic Membrane For Traditional Chinese Medicine Production And Plant Extraction

05 Feb 2019

Ceramic Membrane For Traditional Chinese Medicine Production And Plant Extraction

05 Feb 2019

Application Of Ceramic Membrane Equipment In Transformer Oil And Gas Separation

12 Feb 2019

Application Of Ceramic Membrane Equipment In Transformer Oil And Gas Separation

12 Feb 2019

Ceramic Membranes Are Used In The Automotive Field Due To Their Good Performance

27 Jan 2019

Ceramic Membranes Are Used In The Automotive Field Due To Their Good Performance

27 Jan 2019

+86-25-58849045

+86-25-58849045

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808