Membrane separation technology is widely welcomed by users because of its remarkable energy-saving effect, easy operation and maintenance, and simple control. Choosing the appropriate membrane separation process can replace vacuum filtration, plate and frame pressure filtration, and ion exchange for many traditional separation and filtration methods.

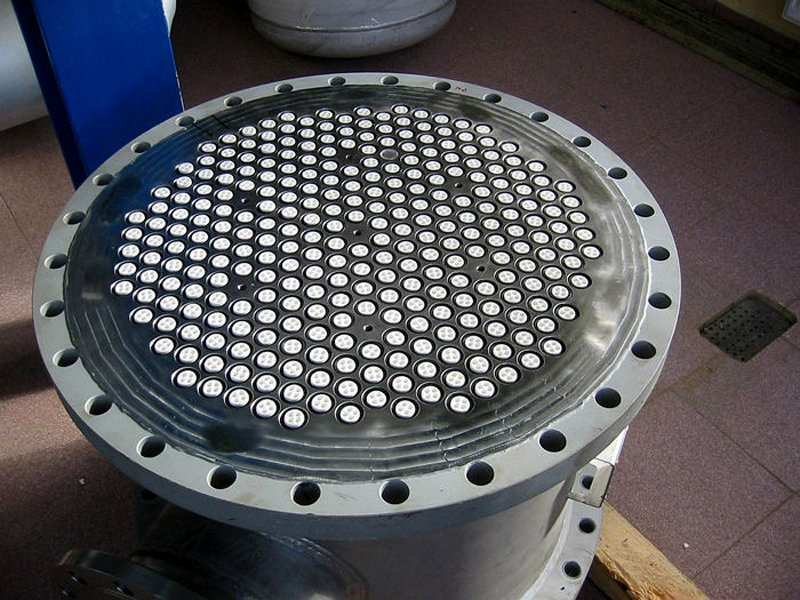

The application of

inorganic membranes mainly involves liquid phase separation and purification, gas separation and purification and membrane reactor. The industrial application of inorganic membranes is mainly concentrated in the field of liquid phase separation. The application of inorganic membranes in liquid separation is mainly microfiltration and ultrafiltration, and the most used inorganic ceramic membranes occupy 80% of the market.

What are the characteristics of membrane separation technology?

Compared with traditional separation techniques such as distillation, adsorption, absorption, extraction, cryogenic separation, membrane separation technology has the following characteristics:

1. Efficient separation process

It can separate substances with a relative molecular weight of several thousand or even hundreds (the corresponding particle size is nanometer).

2. Low energy consumption

Since most membrane separation processes do not undergo phase changes, the latent heat of phase change is large. Traditional separation processes such as freezing, extraction, and flashing are phase changes that typically result in higher energy consumption.

3. Working temperature close to room temperature

Most membrane separation processes operate at temperatures around room temperature, so the membrane itself has a unique advantage in handling heat-sensitive substances. At present, it has its unique promotion and application value especially in the fields of food processing, pharmaceutical industry and biotechnology.

4. Good quality and stability

The

membrane device itself has no moving parts and the operating temperature is near room temperature, so maintenance is rarely required and reliability is high. Its operation is very simple, and the time from the start of the device to the time the product is obtained is very short, and it can be started and stopped frequently. The production cycle can be significantly shortened compared to conventional processes.

5. Continuous operation

The membrane separation process can realize the continuous operation process and meet the actual needs of industrial production.

6. Strong flexibility

The scale and processing capacity of the

membrane equipment is variable, and it is easy to scale up and promote the application. The membrane separation device can be directly inserted into the existing production process, and is easily combined with other separation processes to facilitate the original process reconstruction and the integration of the upper and lower processes.

7. Pure physical process

Membrane separation is a purely physical process, without any chemical changes, and no need to add any substances, such as filter aids, chemical reagents, etc.

8. Environmental protection

The membrane separation equipment is made of clean materials, environmental protection, clean and hygienic work site, in line with national industrial policies.

JIANGSU JIUWU HI-TECH CO. LTD. (Referred to as “

JIUWU HI-TECH”) was founded in 1997. In 2017, JIUWU HI-TECH was listed on the Shenzhen Stock Exchange (stock code: 300631). They have become the largest ceramic membrane manufacturer in the World.

Application Of Ceramic Membranes In Wine Industry And Its Application Prospects

01 Feb 2019

Application Of Ceramic Membranes In Wine Industry And Its Application Prospects

01 Feb 2019

Ceramic Membrane For Traditional Chinese Medicine Production And Plant Extraction

05 Feb 2019

Ceramic Membrane For Traditional Chinese Medicine Production And Plant Extraction

05 Feb 2019

Application Of Ceramic Membrane Equipment In Transformer Oil And Gas Separation

12 Feb 2019

Application Of Ceramic Membrane Equipment In Transformer Oil And Gas Separation

12 Feb 2019

Ceramic Membranes Are Used In The Automotive Field Due To Their Good Performance

27 Jan 2019

Ceramic Membranes Are Used In The Automotive Field Due To Their Good Performance

27 Jan 2019

+86-25-58849045

+86-25-58849045

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808