The study of ceramic membranes began in the 1940s and its development can be divided into three stages. In the nuclear industry for the isotope separation of uranium, a ceramic membrane enrichment plant with a membrane area of 4 million square meters was built in the 1980s. The liquid separation period based on the inorganic

microfiltration membrane and the ultrafiltration membrane and the comprehensive development period centered on the membrane catalytic reaction.

Through the development of these three stages, the inorganic ceramic membrane separation technology has been initially industrialized. After the successful application in the dairy and beverage industry in France in the early 1980s (wine, beer, cider), its technology and industrial status were gradually established. Applications have also expanded to the food industry, bioengineering, environmental engineering, chemical industry, petrochemical, metallurgical industry and other fields.

Inorganic ceramic membrane separation technology has become an important new technology for precision filtration separation under severe conditions.

The dense inorganic film is still in the laboratory research stage, such as metal palladium, silver and its alloy film, perovskite mixed conductor film. It has broad application prospects in the fields of high temperature gas separation and membrane reaction.

At the same time as the development of liquid separation membranes, inorganic membranes have received increasing attention due to their excellent material properties. Membrane catalytic technology using inorganic membrane strengthening reaction process and high temperature gas membrane separation technology has become a research hotspot in many disciplines.

The inorganic separator has a relatively small market share in the field of membranes. In 1997, the US inorganic film market sales were 100 million US dollars, of which ceramic membrane accounted for about 80%, accounting for only 9% of the film market. It is also estimated that by 2004, the market share of the world separation membrane will exceed 10 billion US dollars, and the market share of inorganic membrane will account for 12%. Due to the successful application of

ceramic membranes in precision filtration separation, its market sales have grown at an annual rate of 35%.

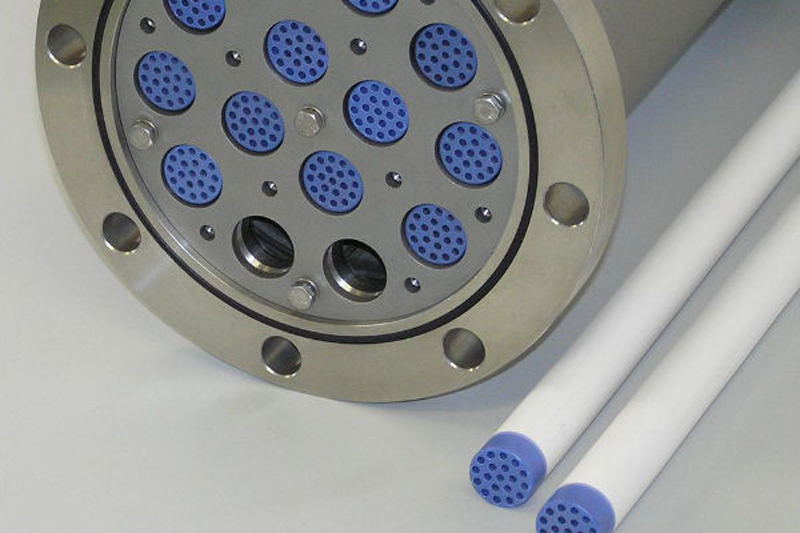

During the “Ninth Five-Year Plan” period, under the strong support of national key scientific and technological projects, the national “863” plan, and the National Natural Science Foundation, Nanjing University of Technology has developed ceramic microfiltration and ultrafiltration membrane scale production technology. Ceramic membrane products have been promoted and applied in the fields of chemical industry, petrochemical industry, food industry, pharmaceutical industry and environmental protection. At present, the membrane area of a single ceramic membrane device has reached 220 square meters. Following the European and American countries, a new industry of ceramic membranes was initially formed.

In the production and application development of ceramic membranes, JIANGSU JIUWU-HITECH CO., LTD. has built three ceramic membrane production lines with an annual output of 10,000 square meters, and has undertaken the special project of industrialization of the State Planning Commission, and is committed to the industrialization of ceramic membranes. In addition, some units are building ceramic membrane production lines or exploring the possibility of introducing production lines from abroad.

With the expansion of the application field, the demand for ceramic membranes will gradually increase. But in the face of fierce competition in international film technology,

JIUWU HI-TECH represents China's leading membrane technology company. Its ceramic membrane industry has a long way to go.

Application Of Ceramic Membranes In Wine Industry And Its Application Prospects

01 Feb 2019

Application Of Ceramic Membranes In Wine Industry And Its Application Prospects

01 Feb 2019

Ceramic Membrane For Traditional Chinese Medicine Production And Plant Extraction

05 Feb 2019

Ceramic Membrane For Traditional Chinese Medicine Production And Plant Extraction

05 Feb 2019

Application Of Ceramic Membrane Equipment In Transformer Oil And Gas Separation

12 Feb 2019

Application Of Ceramic Membrane Equipment In Transformer Oil And Gas Separation

12 Feb 2019

Ceramic Membranes Are Used In The Automotive Field Due To Their Good Performance

27 Jan 2019

Ceramic Membranes Are Used In The Automotive Field Due To Their Good Performance

27 Jan 2019

+86-25-58849045

+86-25-58849045

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808