For half a century, a new membrane technology has been industrially applied every 10 years since membrane separation has changed from laboratory to large-scale industrial applications.

1. Micro filtration technology

Micro filtration technology is one of the most common applications in all membrane processes with the largest total sales. It is mainly used for filtration sterilization in the pharmaceutical industry. The preparation of high purity water is currently the second largest market for micro filtration technology applications. Industrialization has been achieved in many areas of the food industry in recent years and can be used for the clarification of gelatin and glucose. Micro filtration replaces traditional diatomaceous earth filter juices with the same effect as ultrafiltration. Micro filtration has potential markets for drinking water production and municipal wastewater treatment. In addition, with the development of the biotechnology industry, in order to concentrate and separate biological products in the fermentation broth, the market for microfiltration in this field will also become larger and larger.

2. Uf membrane technology

Uf membrane technology has been widely used in the production of integrated circuits for the electronics industry and the water use process in the pharmaceutical industry. The utility model mainly adopts a hollow fiber module, and has large membrane permeation rate and low energy consumption. Uf membrane technology is also used in the food and pharmaceutical industries. Whey Uf membrane technology recovers the protein, which is one of the largest applications in the dairy industry. Ultrafiltration of milk can increase the yield of cheese, and the process is gradually replacing the traditional process, which will have great economic benefits. Uf membrane technology has been widely used abroad to clarify juice, which has not yet been popularized in China. Uf membrane technology has the advantage of maintaining its biological activity and high recovery rate, and its application in this field will grow with the growth of the genetic engineering technology industry.

3. Ro membrane technology

Ro membrane technology has become the most economical means for desalination of seawater and brackish water, preparation of pure water and ultrapure water, and preconcentration of materials. Moreover, with the industrialization of ro membrane technology and membrane modules with excellent performance, the application of reverse osmosis technology ranges from initial desalination to electronics, chemicals, medicine, food, beverage, metallurgy and environmental protection. With the comprehensive promotion of this technology, ro membrane technology will become the main means of solving drinking water in water-scarce areas in the 21st century.

The production and reuse of ro membrane technology in chemical and petrochemical process water, waste liquid treatment, separation of water and organic liquid, electroplating rinse water reuse and metal recovery are being developed. The food industry is using reverse osmosis technology to develop milk processing, sugar concentrate, juice and dairy processing, wastewater treatment, and production of low alcohol and beer.

4. Nanofiltration membrane technology

Nanofiltration membrane technology is a new separation technology developed on the basis of reverse osmosis. Although the history of market development has only been more than 10 years, it has been well applied in the field of water softening, purification, separation and concentration of antibiotics, polysaccharides and dyes. It can replace or partially replace processes such as precipitation, evaporation and pH adjustment, and become an important energy-efficient unit operation for biopharmaceuticals and fine chemicals. Nanofiltration membrane technology can also be used for food bleaching, ammonia acid separation, peptide purification and concentration.

5. Dialysis and electrodialysis

Dialysis is the first membrane phenomenon discovered and studied. Dialysis technology is mainly used to remove low molecular components in solution, such as salt and other small molecule solutes from serum proteins and vaccines. Although dialysis technology was once replaced by the development of ultrafiltration technology, it has been widely reused in recent years with the development of artificial kidneys, and has become one of the important means of medical treatment for removing blood from patients with renal failure or uremia. It saves nearly a million lives every year.

6. Gas membrane separation technology

Gas membrane separation technology can be widely used in membrane hydrogen extraction, membrane oxygen enrichment, nitrogen enrichment, industrial gas dehumidification, natural gas dehumidification, extraction and removal of organic vapor, carbon dioxide and hydrogen sulfide. Industrial applications that have been and are being developed include:

(1) The recovery technology of H2 in synthetic ammonia relaxation gas has been successful. However, the condensable gases H2O and NH3 should be removed in advance;

(2) The O2/N2 enrichment industry can enrich 95% N2. Highly selective membranes will improve the membrane's position in the field of air nitrogen enrichment;

(3) Acid Gas/Hydrocarbons CO2 has been successfully recovered from biogas, but condensable organics should be removed beforehand, and a suitable separation factor is required to ensure yield. There are no ready-made devices for removing H2S from acid gases, but membranes currently under development can be applied.

7. Inorganic membrane

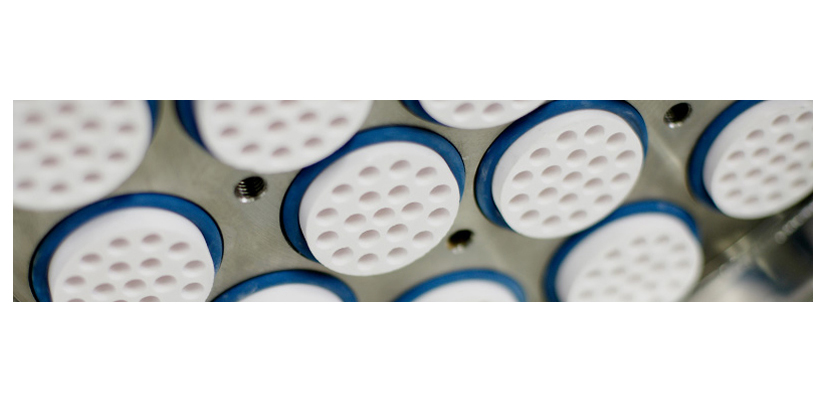

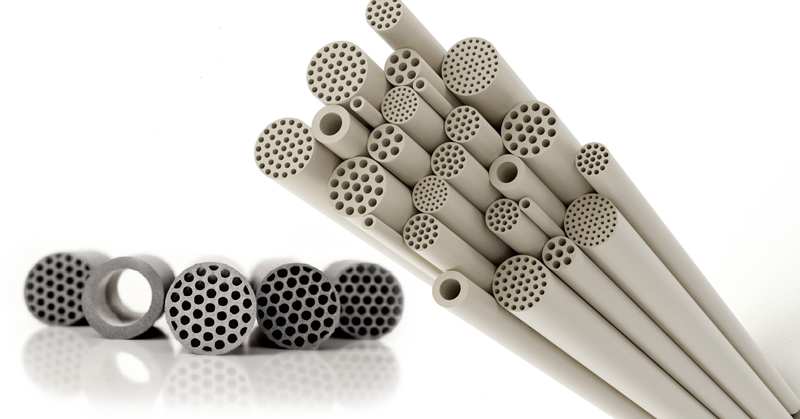

Inorganic membranes mainly include

ceramic membranes, metal oxide membranes (such as Υ-Al2O3, ZnO, TiO2) and metal membranes, etc., which are suitable for use under high pressure, high temperature, high viscosity, high solid content, high chloride content and harsh pH conditions. . Therefore, it has broad application prospects in the fields of petrochemical, food, metallurgy, environmental engineering, and bioengineering.

After five years of efforts in China's inorganic membranes, ceramic microfiltration membranes and

ultrafiltration membranes have been industrialized from the ground up. The technical indicators of membrane materials and the scale and automatic control of membrane equipment have reached the international advanced technology level.

JIUWU HI-TECH is the largest

membrane supplier in China. In the future, inorganic membranes will play an important role in gas separation and purification, and through the combination of inorganic membranes and other processes, and transformation of traditional processes, and gradually form a new integrated application technology with inorganic membranes as the core.

Application Of Ceramic Membranes In Wine Industry And Its Application Prospects

01 Feb 2019

Application Of Ceramic Membranes In Wine Industry And Its Application Prospects

01 Feb 2019

Ceramic Membrane For Traditional Chinese Medicine Production And Plant Extraction

05 Feb 2019

Ceramic Membrane For Traditional Chinese Medicine Production And Plant Extraction

05 Feb 2019

Application Of Ceramic Membrane Equipment In Transformer Oil And Gas Separation

12 Feb 2019

Application Of Ceramic Membrane Equipment In Transformer Oil And Gas Separation

12 Feb 2019

Ceramic Membranes Are Used In The Automotive Field Due To Their Good Performance

27 Jan 2019

Ceramic Membranes Are Used In The Automotive Field Due To Their Good Performance

27 Jan 2019

+86-25-58849045

+86-25-58849045

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808